Digitalya Overview

Digitalya is a leading technology company based in Romania, specifically in the bustling city of Iași. Established in 2013, we specialize in providing top-notch services in User Experience (UX/UI) des... Read More

Services

39 services offered by DigitalyaReviews

0 reviews for DigitalyaPortfolio

8 projects performed by Digitalya

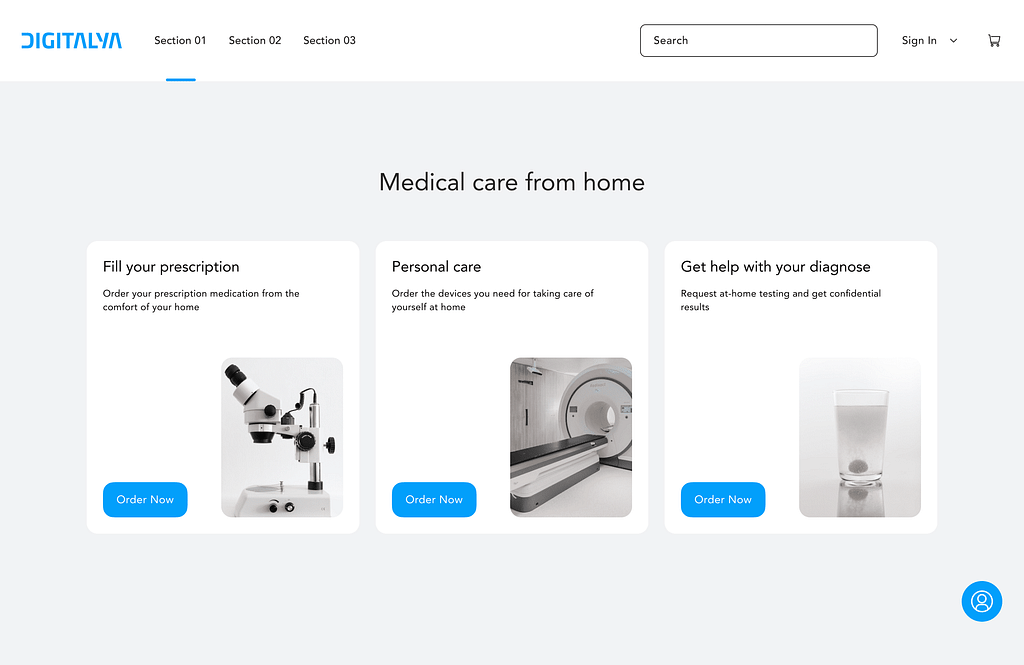

This project focuses on enhancing the top telemedicine app in the US by introducing new features to improve the overall user experience and functionality of the platform.

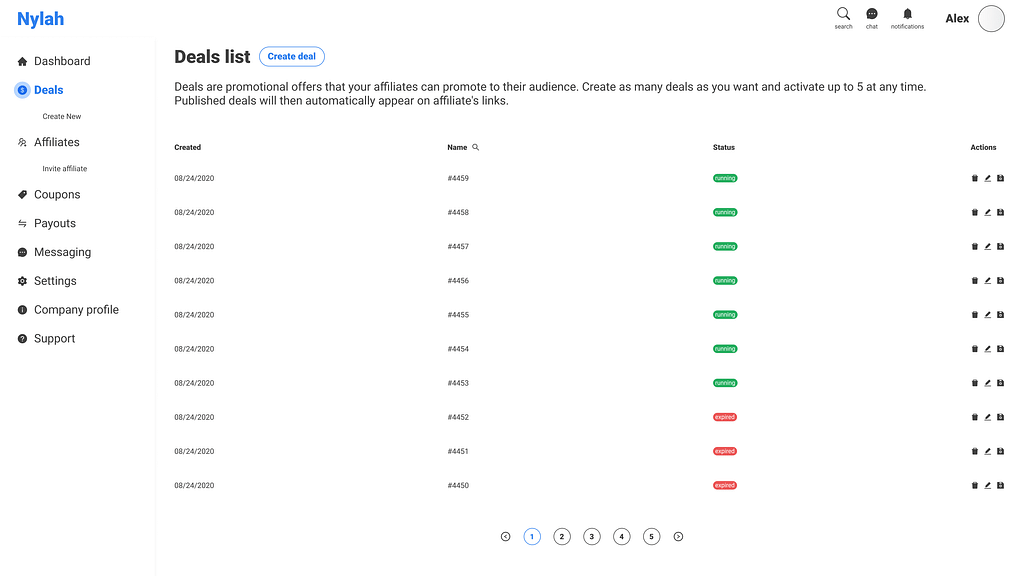

Our Influencer Affiliate Marketing Platform is a cutting-edge software solution that connects brands with influencers to create mutually beneficial partnerships. By leveraging the power of social media influencers, brands can reach a wider audience and increase their sales and brand awareness.

The All-in-one training management system is a comprehensive platform designed to streamline and automate the process of organizing and delivering training programs. It allows organizations to easily create, schedule, and track training sessions for employees and external stakeholders.

Our Omnichannel platform for big pharma companies is a comprehensive software solution designed to streamline communication and engagement with healthcare professionals, patients, and other stakeholders across various channels.

The Real-time feedback web app is a platform designed to collect and analyze user feedback instantly. It allows businesses to gather valuable insights from their customers in real-time, enabling them to make data-driven decisions to improve their products or services.

Medical quiz assessment with data-driven analytics is a project aimed at improving healthcare education and training through interactive quizzes and advanced analytics. This project combines medical knowledge with technology to create a dynamic learning experience for healthcare professionals and students.

Our Audit software for aviation enterprises is a comprehensive solution designed to streamline and automate the auditing process for aviation companies. It offers a user-friendly interface and powerful features to help organizations easily conduct audits and ensure compliance with industry regulations.

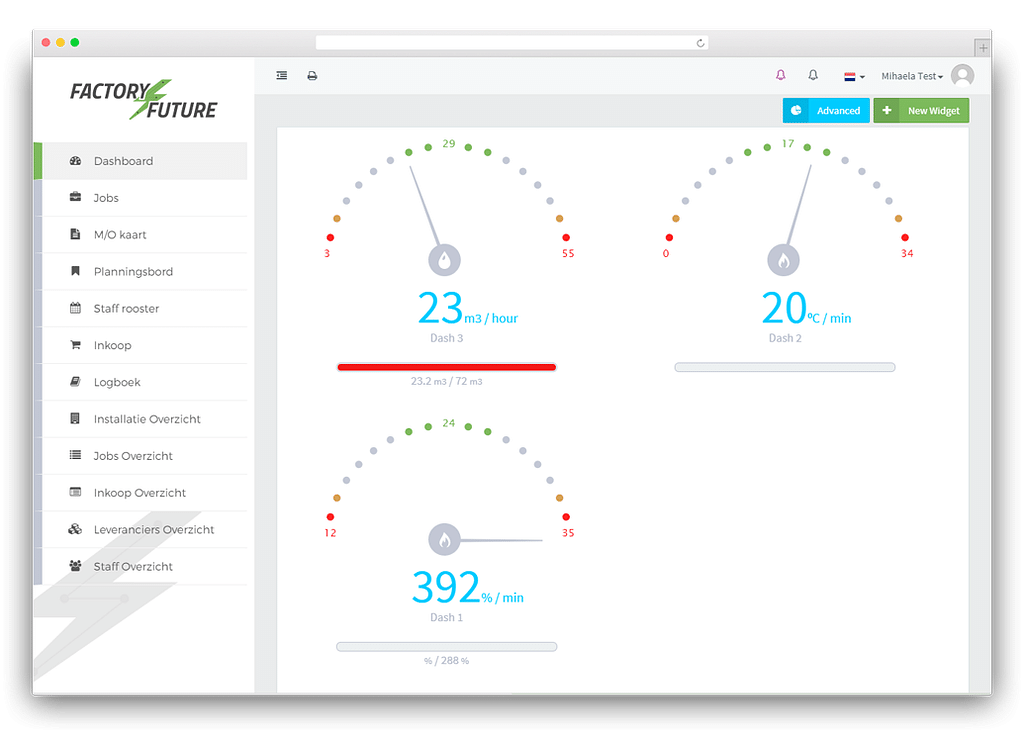

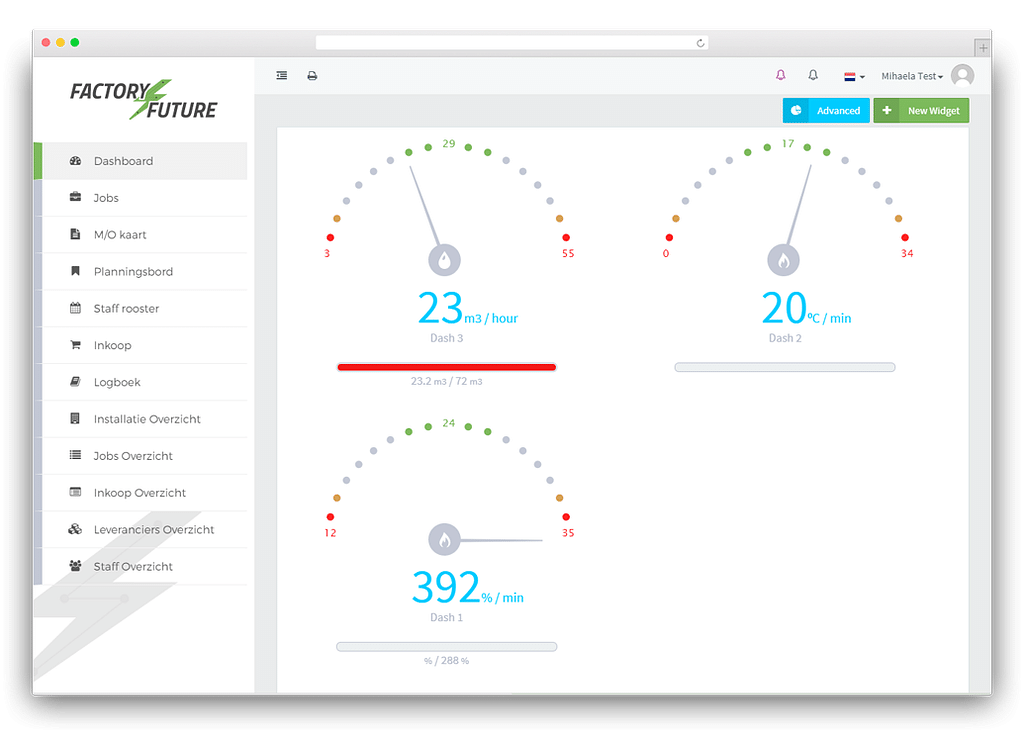

Factory automation - IoT cloud-based application is a cutting-edge technology solution designed to streamline and optimize manufacturing processes through the use of Internet of Things (IoT) devices and cloud computing. This innovative application allows for real-time monitoring, analysis, and control of factory equipment and operations, leading to increased efficiency and productivity.

Factory automation - IoT cloud-based application

by Digitalya

Description

Factory automation - IoT cloud-based application is a cutting-edge technology solution designed to streamline and optimize manufacturing processes through the use of Internet of Things (IoT) devices and cloud computing. This innovative application allows for real-time monitoring, analysis, and control of factory equipment and operations, leading to increased efficiency and productivity.

Challenge

One of the main challenges faced by manufacturers is the lack of real-time visibility and control over their production processes. Traditional factory automation systems are often isolated and not easily scalable, leading to inefficiencies and downtime. Additionally, integrating IoT devices and cloud technology into existing systems can be complex and costly.

Solution

Our Factory automation - IoT cloud-based application addresses these challenges by providing a centralized platform for monitoring and managing all factory equipment and processes in real time. By leveraging IoT sensors and devices, data is collected and analyzed to optimize production workflows and predict maintenance needs. The cloud-based nature of the application ensures scalability, flexibility, and cost-effectiveness.

Impact

By implementing our Factory automation - IoT cloud-based application, manufacturers can expect significant improvements in efficiency, productivity, and overall performance. Real-time monitoring and predictive maintenance features help reduce downtime and maintenance costs, while optimizing production output. The streamlined workflow and data-driven insights provided by the application empower manufacturers to make informed decisions and stay competitive in the market.